MCube RFP: Early Detection of Costly Roller Failures with Real-Time Monitoring

Poing near Munich, June 25th, 2025 – Roller failures account for 75% of all mechanical faults on conveyor belts. These failures often lead to unexpected production halts, high energy costs, and safety risks. REMA TIP TOP's innovative MCube RFP system precisely detects vibrations and can be seamlessly integrated into existing maintenance processes for predictive maintenance.

Tire Repair: An Economical Solution for Truck Fleets

Poing near Munich, May 20th, 2025 – Dealing with rising costs is a key challenge for many companies in the transportation and logistics sector. Raw material prices are rising, environmental regulations are becoming stricter, and pressure to reduce costs is constantly growing. In this environment, professionally repairing truck and industrial off-the-road (OTR) tires is becoming increasingly important. It is a practical, economical alternative to expensive new purchases, and sustainable repair systems help companies counteract rising costs.

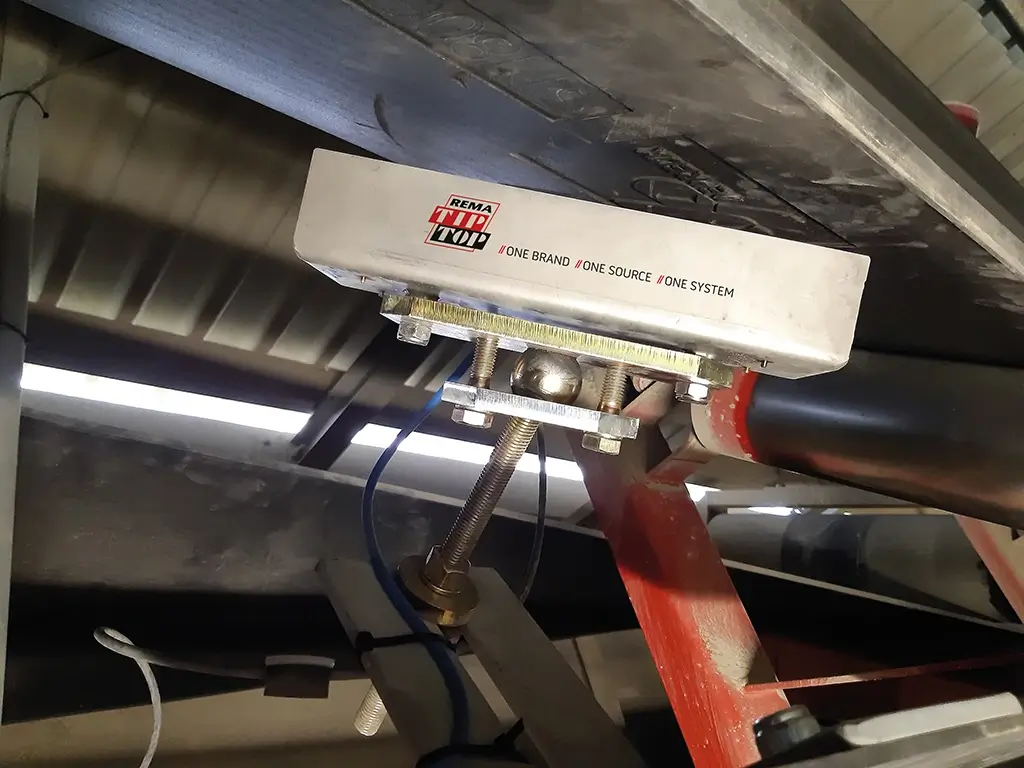

MCube BRD2: Operational Safety on a New Level

Poing near Munich, March 24th, 2025 – REMA TIP TOP presents MCube BRD2, the latest generation of Belt Rip Detection (BRD). The innovative sensor technology significantly improves the precise real-time analysis of steel cord conveyor belts and supports predictive maintenance. Belt rips are detected quickly and reliably. An automatic halt prevents significant damage and reduces repair costs and expensive production downtime to a minimum - a real added value for plant operators in the mining and heavy industries. MCube BRD2 is part of the comprehensive REMA Engineered Technologies portfolio that REMA TIP TOP provides to optimize the maintenance of conveyor belts.

The Evolving Bicycle Market: REMA TIP TOP Strengthens the Industry with Innovative Solutions

Poing near Munich, February 25th, 2025. The bicycle industry is changing: e-bikes are conquering the roads and the bicycle is becoming a symbol of a conscious, sustainable lifestyle. Alexander Schall, who has been Key Account Manager for two-wheelers at TIP TOP Automotive GmbH for a year now, talks in an interview about the positive market dynamics, the rediscovery of classic products and his plans to strengthen and expand REMA TIP TOP's role in the two-wheeler sector with innovative repair and workshop equipment.

Cost Savings and Sustainability in the OTR Tire Market: REMA TIP TOP Delivers Innovative Repair Solutions

Poing near Munich, January 23, 2025. Reducing costs and protecting the environment – these two trends are decisive in the growing market for off-the-road (OTR) tires. The proven REMA TIP TOP repair system for these special tires is therefore becoming increasingly important. "We enable the construction and mining industries to significantly extend the service life of their tires through safe, cost effective and environmentally friendly repairs," says Matthias Ziller, Global Application & Product Management Automotive at REMA TIP TOP AG.

REMA TIP TOP Supports Lenzing with Critical Conveyor Technology in Pulp Mill

Poing near Munich, December 4, 2024 - At the pulp plant of the international fiber manufacturer Lenzing in central Austria, uninterrupted material transport is the be-all and end-all for a smooth production process.

REMA TIP TOP UK is NTDA Supplier of the Year 2024

Poing near Munich, November 11, 2024 - REMA TIP TOP Automotive UK has been awarded the prestigious NTDA Aftermarket Supplier of the Year Award 2024. The award, which was presented at the 95th

New Production Plant in Poing: More Energy Efficiency in Operations at REMA TIP TOP

Poing, Near Munich, Germany, October 31st, 2024. REMA TIP TOP is converting its production of adhesive systems and solutions in Poing near Munich to new, innovative processes and technologies. In this way, the amount of energy used in the production of adhesive systems can be reduced significantly.

Tire Repair: The Key to more Environmentally Friendly Mobility

Poing near Munich, September 9, 2024: More than 300 million car, van and truck tires are replaced every year in Europe to replace worn or defective tires, around 45 million of them in Germany alone. Most car drivers and many commercial enterprises are still missing out on huge potential savings for the environment and mobility costs.

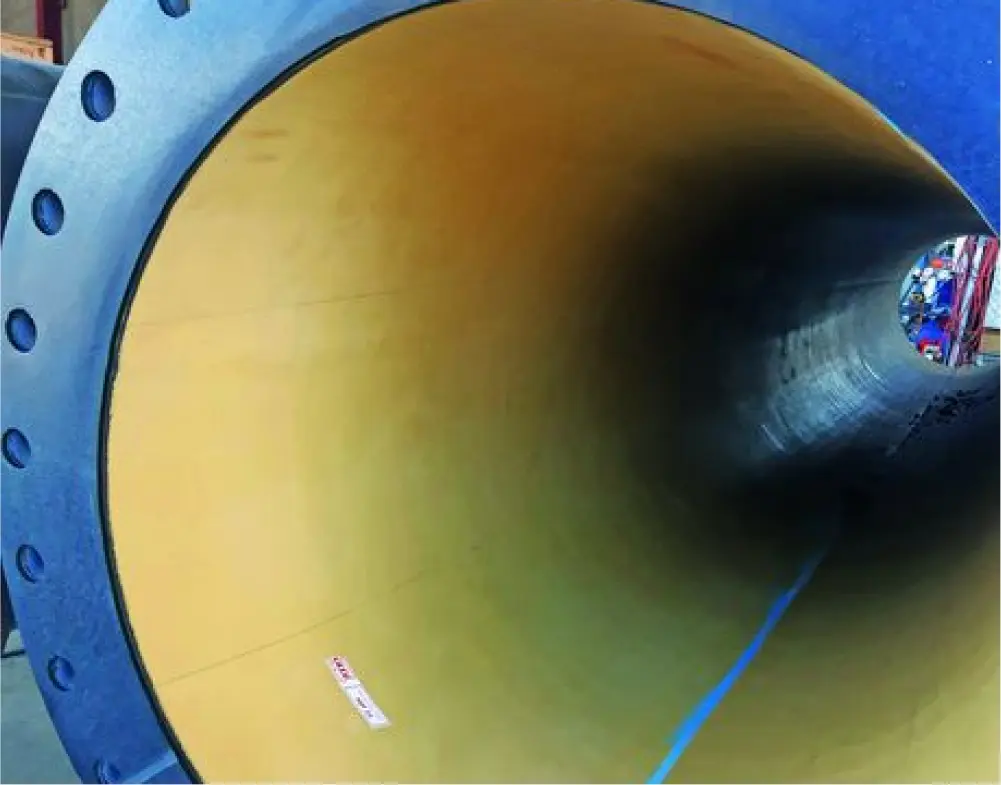

Interview: Rubber for Effective Wear Protection in Conveyor Systems

Poing near Munich, July 22, 2024 - Rubber is the material of choice for protecting surfaces in conveyor systems for light and medium-weight materials against wear. However, not all rubber is the same and not every elastomer is equally suitable for every requirement. Rico Harting, Product Manager at wear protection specialist REMA TIP TOP, has been developing solutions for efficient and sustainable wear protection in conveyor systems for many years.